High Efficiency Centrifugal Slurry Pump For Mining Tailings / Power

4 / 3 C -

Product overview

series horizontal centrifugal slurry pump is the machine transfer

high hardness substance like slurry (slurry is the abrasive and

corrosive medium mixed with water), ore slag, clay slag, iron slag,

sand etc. usually used in the mining, coal / gold washing, power

plant and sewage water treatment. The temperature of the pumped

solid-liquid mixture should be ≤80oC, and the weight concentration

should be ≤60.

This horozontal single stage diesel water centrifugal pump, made of

high chrome alloy or rubber materials and equipped with a

double-layer casing, enjoys a longer servide lifespan. Its frame

plates are made of hard metal or pressure moulded elastomer liners.

So are its impellers.

4 /3 C - Parameter

Allowable Max.Power:30 kw

Capacity:86.4 - 198 m³/h

Head:9 - 52 m

Speed:1000 - 2200 r/min

Max.Efficiency:71%

NPSH:4 - 6 m

Impeller Diameter:245 mm

Typical Applications:

-Ash Handling

-Cyclone Feeds

-Pulp and Paper

-Abrasive Slurries

-Coal Preparation

-Mineral Processing

-Aggregate Processing

Feature

1. The frame plates for slurry pump have replaceable wear-resistant

metal liners or rubber liners.

2. The impellers are made of wear-resistant metal or rubber. The

frame plate liner and impeller for slurry pump are adoptable of

hard metal only.

3. Bearing assembly use cylindrical structure,adjusting the space

between impeller and front liner easily, being removed completely

when being repaired. Bearing assembly use grease lubrication.

4. The shaft seal could use the packing seal, expeller seal and

mechanical seal.

5. The discharge branch can be positioned at intervals of 45

degrees by request and oriented to any eight positions to suit

installations and applications

Seal Type:

1. Expeller drive seal: Use pressure seal produces by impeller and

expeller in series, packing or lip sealing ring for shut down seal.

2. Packing seal: The routing sealing systems are suitable for

various conditions and can be used in the corrosin or high

temperature conditions such as polytetrafluoroethylene packing,

graphite packing and etc. It also can be used in strong abrasive

condition duty eith shaft ceramic sleeve of sprey weld.

3. Mechanical Seal: World-advanced sealing technique without

sealing leakage, integrating construction installation &

replacement, various construction suit for all kinds of conditions.

High hardness creamic and alloy are adopted for material of

friction parts. Design & macting of mechanical seal & sealing box

is suitable for fluid state. It possesses high abrasive resistance

& shakeproof to guarantee that sealing seffect can be satisfied by

customers in various conditions.

Type meaning

| Type meaning for 4 /3 C - (R) |

| 4/3C-(R) slurry pump |

| 4 | Pump inlet size (inch) |

| 3 | Pump outlet size (inch) |

| E | Bracket type |

| Pump model |

| R | R-Rubber liner pump |

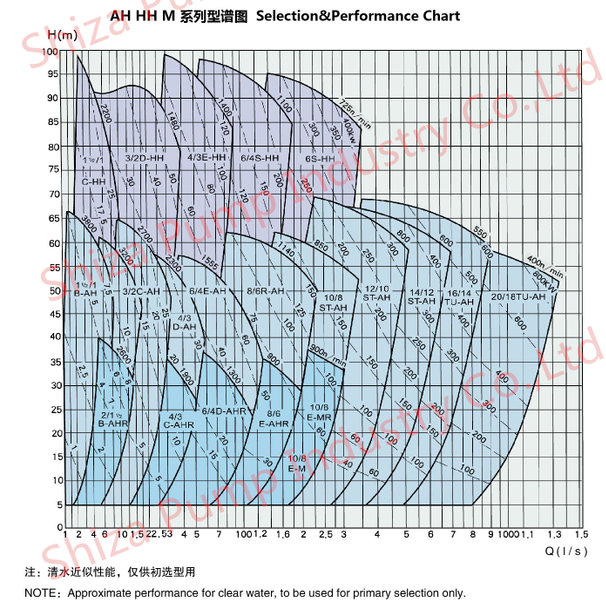

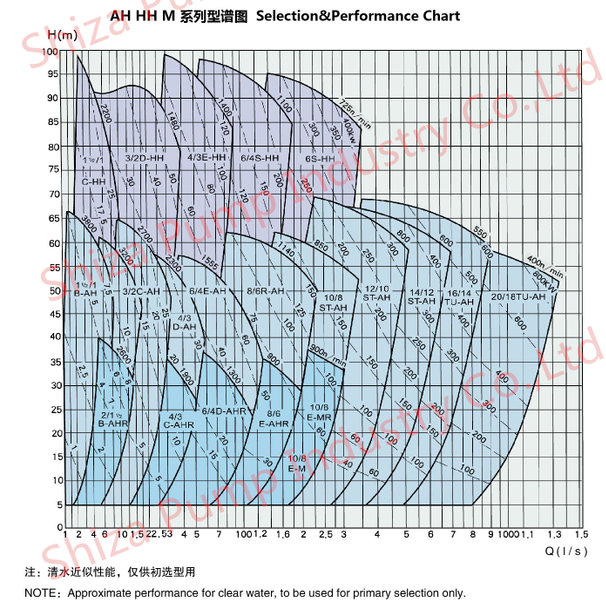

Performance table of (R)/HH centrifugal slurry pump

| MODEL | ALLOWABLE MATING

MAX.POWER

(KW) | MATERIAL | CLEAN WATER PERFORANCE | IMPELLER |

| LINER | IMPELLER | Q Capacity | H Head | Speed | Max. Eff. | NPSH | VANES NO. | IMPELLER DIA |

| m3/h | L/s | (m) | n(r/min) | (%) | (m) | | (mm) |

| 1.5/B- | 15 | M | M | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2--4 | 5 | 152 |

| RU | RU | 10.8-25.2 | 3--7 | 7-52 | 1400-3400 | 30 | 3 |

| 1/1.5B- | 15 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 |

| 2/1.5B- | 15 | M | M | 32.4-72 | 9--20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 |

| RU | RU | 25.2-54 | 7--15 | 5.5--41 | 1000-2600 | 50 | 2.5-5 | 5 | 178 |

| 3/2C- | 30 | M | M | 39.6-86.4 | 11--24 | 12-64 | 1300-2700 | 55 | 4--6 | 5 | 214 |

| RU | RU | 36-75.6 | 10--21 | 13-46 | 1300-2300 | 60 | 2--4 | 5 | 213 |

| 3/2D-HH | 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 |

| 4/3C- | 30 | M | M | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4--6 | 5 | 245 |

| RU | RU | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3--5 |

| 4/3E-HH | 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2--5 | 5 | 508 |

| 6/D- | 60 | M | M | 162-360 | 40-100 | 12-56 | 800-1550 | 65 | 5--8 | 5 | 365 |

| RU | RU | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3--5 | 5 | 365 |

| 6/4S-HH | 560 | M | M | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 5 | 711 |

| 6S-HH | 560 | M | M | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 5 | 711 |

| 8/6E- | 300 | M | M | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 |

| RU | RU | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 5 | 510 |

| 10/8E-M | 120 | M | M | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4-10 | 5 | 549 |

| 10/8ST- | 560 | M | M | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 5 | 686 |

| RU | RU | 540-1118 | 150-330 | 12-50 | 400-750 | 75 | 4-12 |

| 12/10ST- | 560 | M | M | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

| RU | RU | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | |

| 14/12ST- | 560 | M | M | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-8 | 5 | 965 |

| RU | RU | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3-10 | |

| 16/14TU- | 1200 | M | M | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 5 | 1067 |

| 20/18TU- | 1200 | M | M | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 5 | 1370 |

(R)/HH/M(R) Series Slurry Pump Construction Design

Selection And Performance Chart