Wear Resistant Single Suction Centrifugal Slurry Pump , CE And ISO

Approved

Product overview

The lining of 8/6E- is made of high-chromium wear-resistant alloy.

Lining is used for wear-out, extending maintenance intervals and

reducing operating costs. The direction of the pump outlet can be

rotated by 8 angle installation.Widely used in

metallurgical,mining,coal,power,building material and other

industrial departments etc.

Designed and bulit for long life with low maintenance:

1. Shaft Sleeve: A hardened, heavy-duty corrosion-resistant sleeve

with “O” Ring seal at both ends protects the shaft. A slip fit

allows the sleeve removed or installed quickly.

2. Centrifugal Shaft Seal: A large precentage of duties allow the

use of the centrifugal seal which eliminates the need of sealing

water.

3. Gland Shaft Seal: Apacked gland type shaft seal is also

acailable and can be fitted with a low flow or a full flow flish

seal water arrangement.

4. Shaft and Bearing Assembly: A large diameter shaft with a short

overhang minimizes deflection and vibration. Heavy -duty roller

bearings are housed in a removable bearing cartridge.

5. Pump Base: A minimum number of through bolts hold the pump

casing to a the frame. A means of impeller adjustment is provided

in a convenient positopn below the bearing housing.

6. Outer casing: Split outer casing halves of cast or dectile iron

contain the wear liners and provide high operation pressure

capabilities.

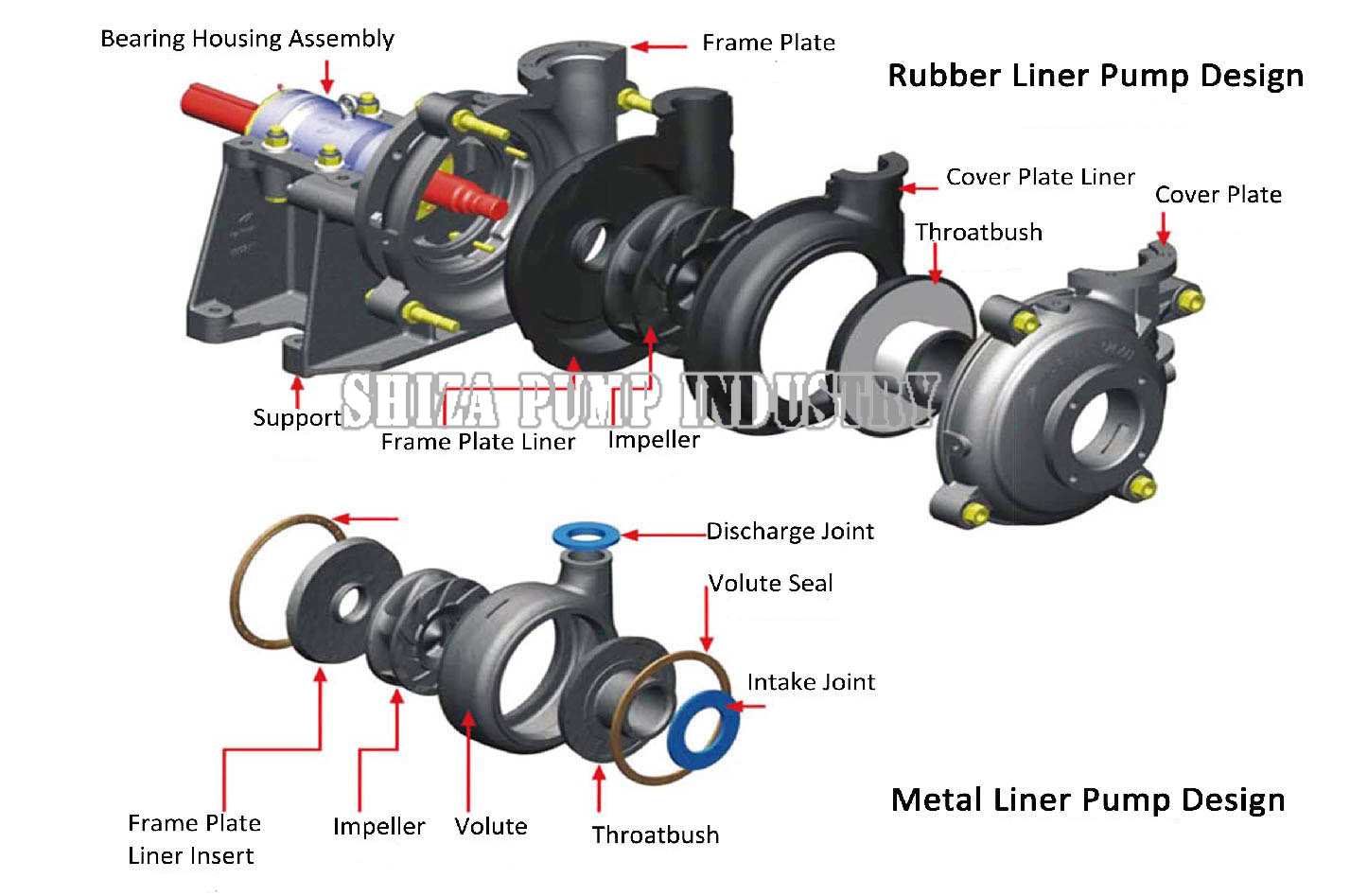

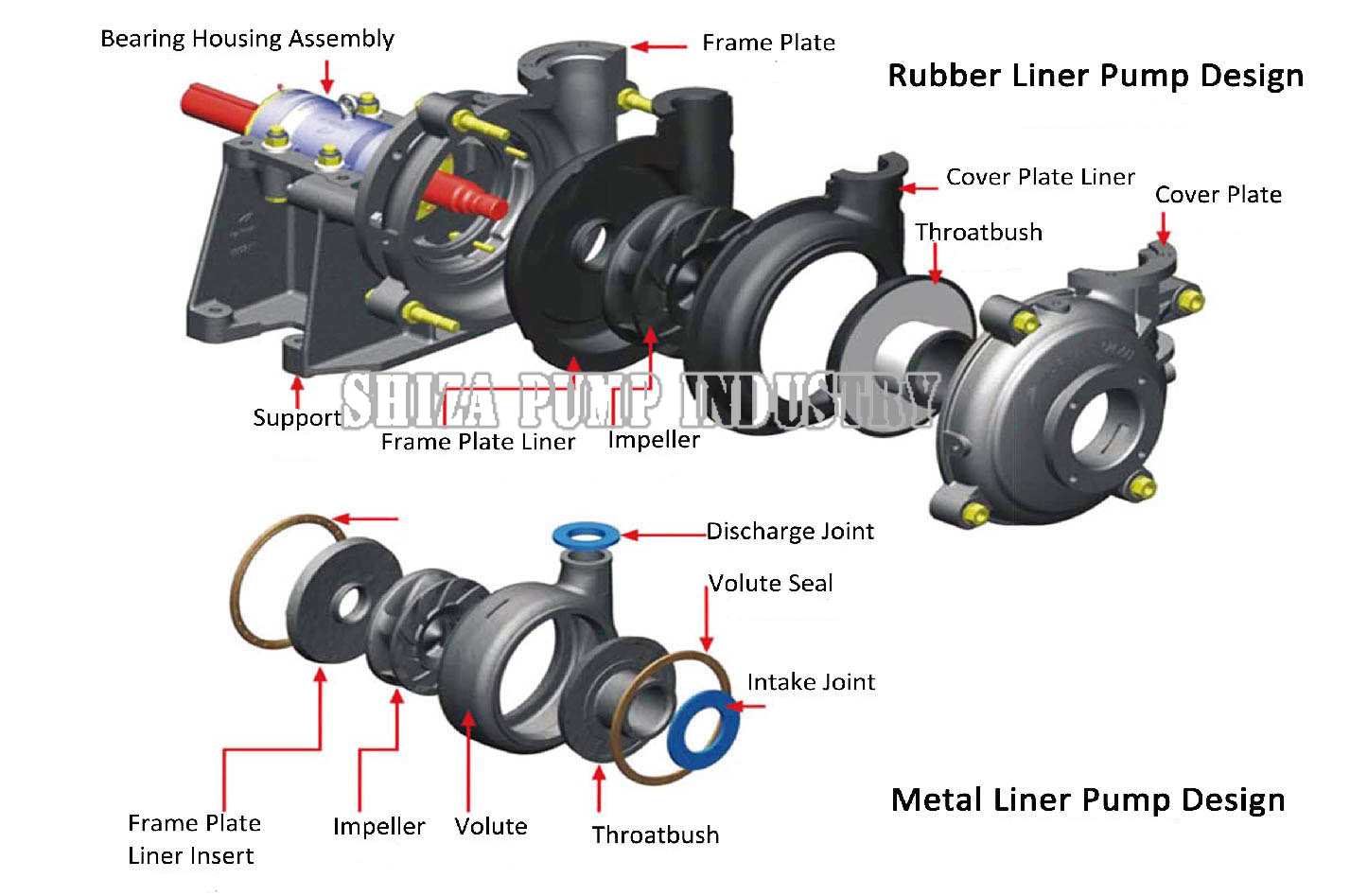

7. Impeller: The impeller may be either moulded elastomer or hard

metal. Deep size sealing canes relieve seal pressure and minimize

recirculation. Cast-in impeller threads are better suited for

slurries.

8. Interchangeable Hard Metal and Moulded Elastomer Liners: Mating

faces in hard metal liners are tapered to allow positive alignment

during assembly and allow components to be easily removed for

replacement. Hydraulic seal rings give positive sealing between

mating faces

Specifications

| Pump Model | 8 / 6 E - |

| Allowable Max.Power | 120 kw |

| Capacity | 360-828 m³ / h |

| Head | 10-61 m |

| Speed | 500-1140 r / min |

| NPSH | 2-9 m |

| Max.Efficiency | 72% |

| Impeller Diameter | 510 mm |

Type meaning

| Type meaning for mineral centrifugal slurry pump |

| 8/6E- |

| 8 | Pump inlet size |

| 6 | Pump outlet size |

| E | Bracket type |

| slurry pump |

| R | R-Rubber liner pump |

Advantages of 8/6 E- slurry pump

-Wear resistant metal or rubber wet end parts, long service life

-Wide options for impeller

-Various types of pump seals to suit different working condition

-Grease or oil lubrication

-Discharge branch can be positioned at intervals of 45 degree

-Can be installed in multistage series

-Easy to maintain

Structure of slurry pump

Shaft Seal Module Design