High Concentration And Strong Abrasive Slurry Pump For Mining And

Metallurgical

Product overview

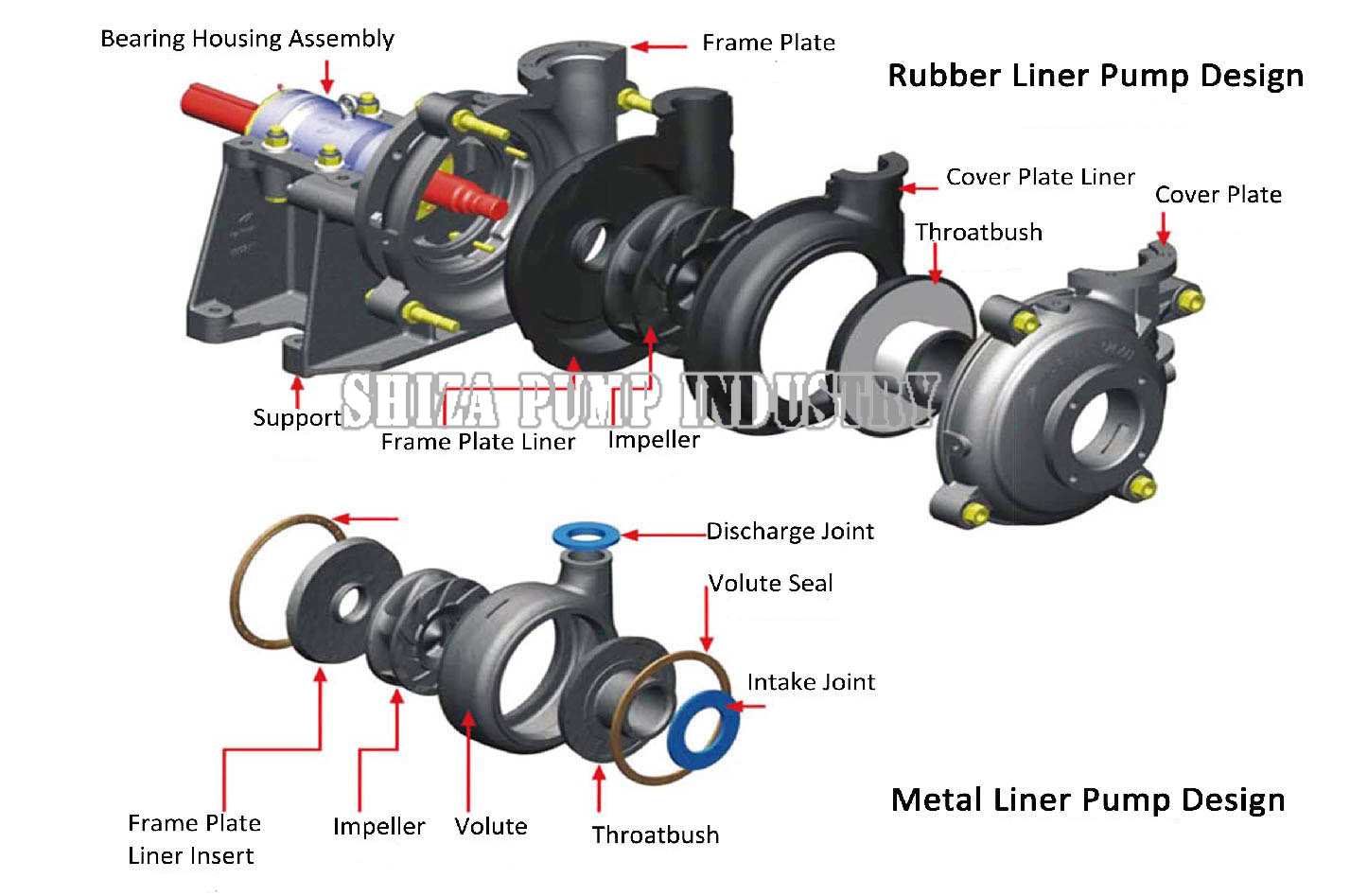

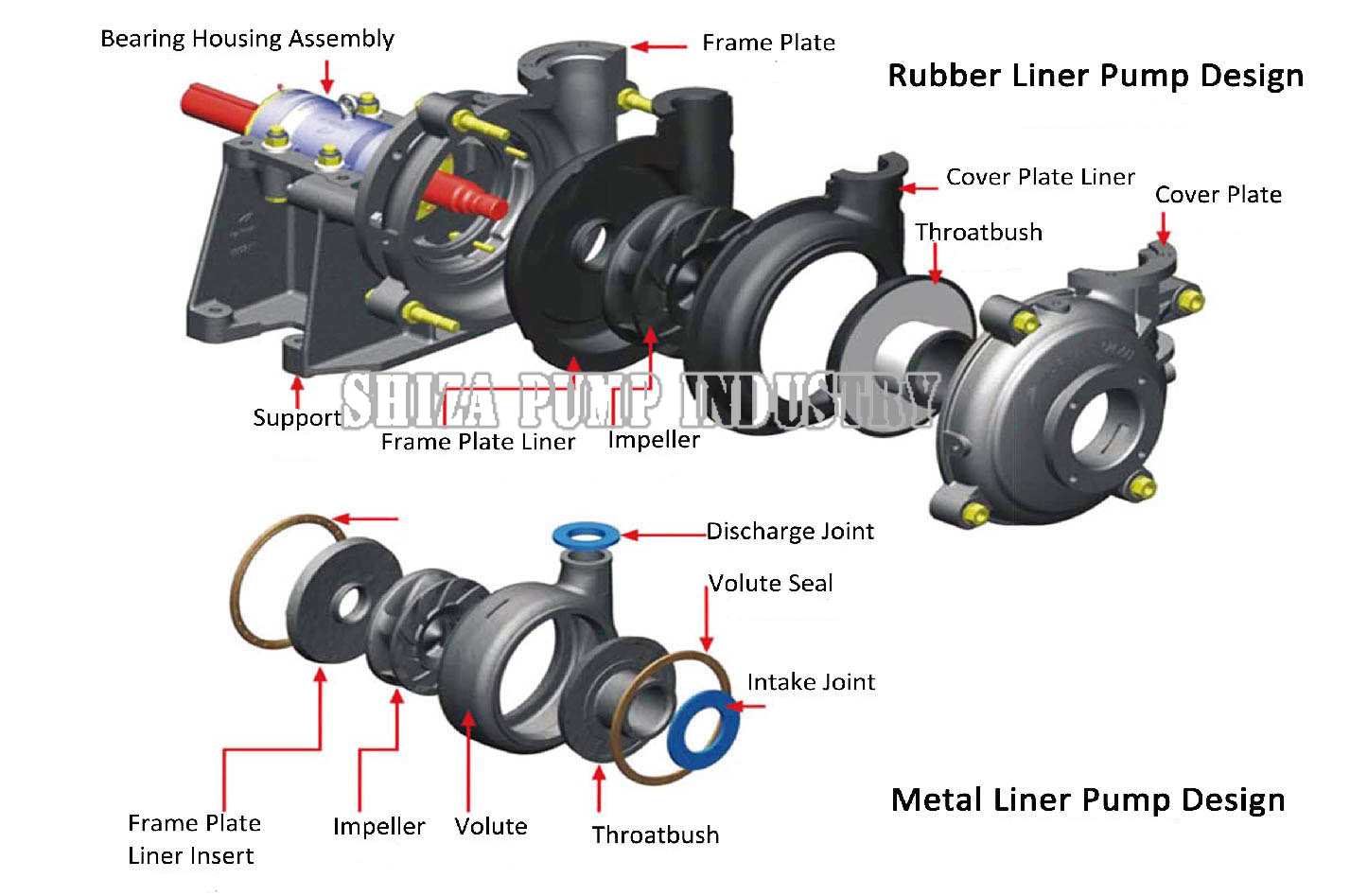

1. The frame plates for pumps have replaceable wear-resistant metal

liners or rubber liners. The

impellers are made of wear-resistant metal or rubber. The frame

plate liner and impeller for HH pump

are adoptable of hard metal only.

2. Bearing assembly use cylindrical structure,adjusting the space

between impeller and front liner easily,

being removed completely when being repaired. Bearing assembly use

grease lubrication.

3. The shaft seal could use the packing seal, expeller seal and

mechanical seal.

4. The discharge branch can be positioned at intervals of 45

degrees by request and oriented to any

eight positions to suit installations and applications.

5. There are the drive types, such as V belt drive, gear reducer

drive, fluid coupling drive, frequency conversion drive devices.

6. Wide performance, good NPSH and high efficiency. The pump of

this type may be installed in

multistage series to meet the delivery for long distance.

Working Principle

1. Before the pump works, the slurry pump bearing, the staff must

first inject the liquid used for conveying into the pipeline and

the pump casing, and fill the two;

2. When the slurry pump is started, the liquid in the impeller will

be rotated by the blades of the impeller;

3. Under the action of centrifugal force, the liquid rotates

forward and then flows out of the impeller;

4. In the process of liquid flowing from the impeller inlet to the

impeller outlet, the slurry pump forum, the speed energy and the

pressure energy are increased due to the energy conversion, and the

liquid flowing out from the impeller is discharged through the pump

casing flow passage and then discharged from the discharge pipe;

5. At this time, the impeller inlet is formed by the discharge of

water, and the slurry pump, the liquid in the suction surface is

pressed into the water inlet of the impeller under the action of

atmospheric pressure;

6. The rotating impeller continuously draws in and vents water to

form a continuous stream of water.

Intruction

1.This series of slurry pumps is an energy efficient, single stage,

single suction, cantilever centrifugal pump for conveying abrasive

or corrosive slurries containing solid particles. Widely used in

power, mining, metallurgy, coal, building materials, chemicals,

food, water conservancy and sewage treatment industries. The large

weight concentration of the solid-liquid mixture is 45% for the

mortar and 60% for the slurry.

2, this series of pumps has more than 50 basic models, slurry pump

design, through the variable speed can get more than 300 kinds of

performance for users to choose.

3, the material of the flow component should be based on the

physical (particle composition, particle size, shape, hardness,

concentration) and chemical (acid, alkali, oil) characteristics of

the transport slurry.

4. The transmission mode of the pump has two forms: direct

transmission and belt transmission, which are divided into DC, HC,

CR, CL, ZV, CV and other modes. (See Appendix 3 for details.) From

the direction of the prime mover, the pump rotates clockwise.

Type Notation

| Type meaning for 8 / 6 R - (R) centrifugal slurry pump |

| 8/6R- |

| 8 | Pump inlet size |

| 6 | Pump outlet size |

| R | Bracket type |

| slurry pump |

| R | Natural Rubber |

Specification

| Model | 8 / 6 R - (R) |

| Allowable Max.Power | 300kw |

| Capacity | 324 - 720m³//h |

| Head | 7-49m |

| Speed | 400-1000r/min |

| Max.Eff. | 65% |

| NPSH | 5-10m |

| Impeller Dia. | 510mm |

Structure of 8 / 6 R - (R)